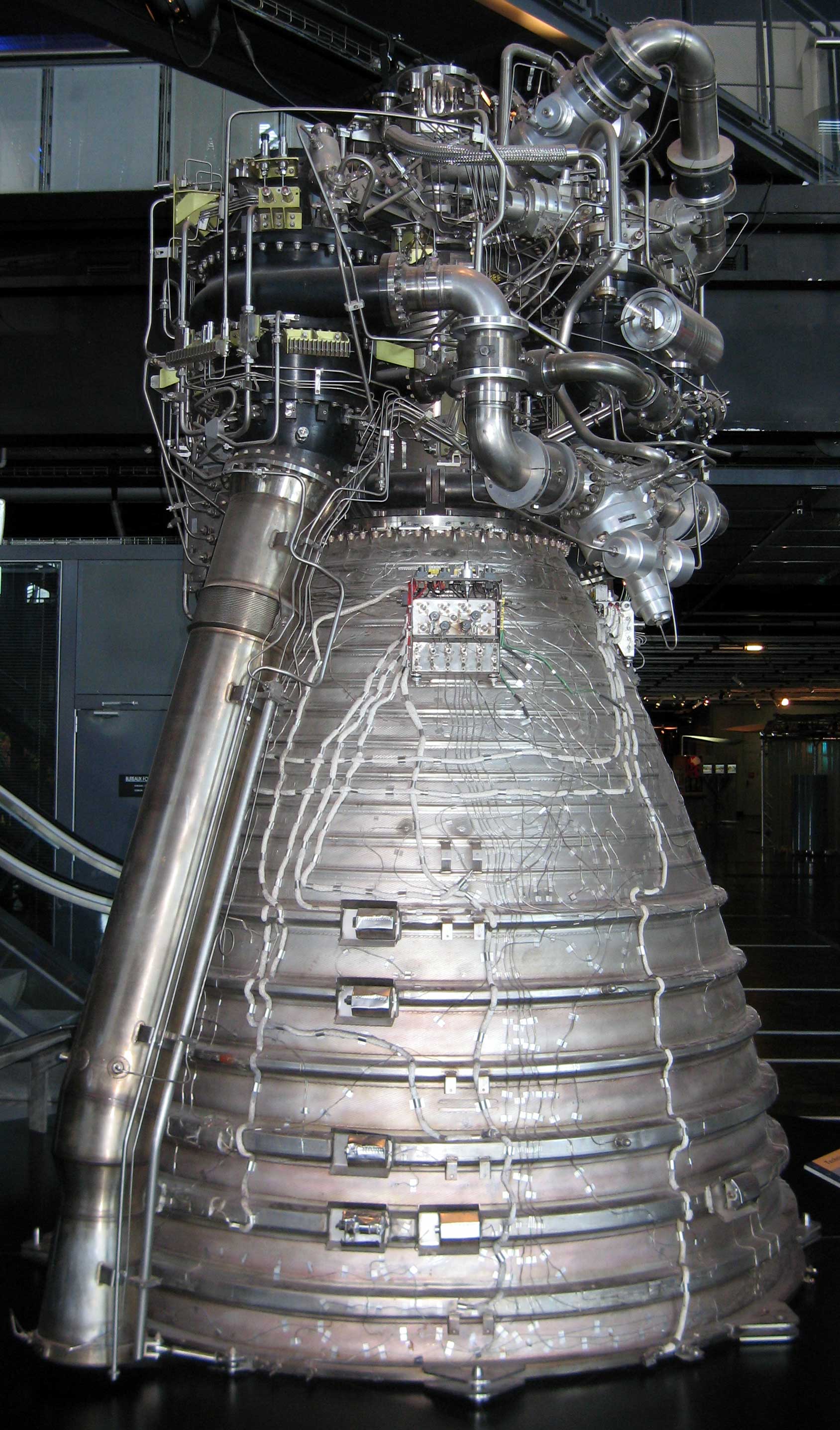

Cryogenic Treatment Of Engine Parts

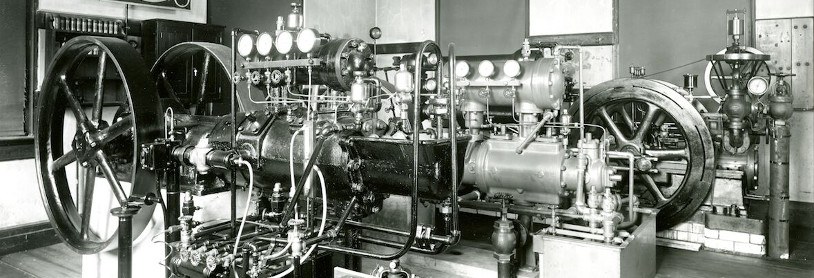

Cryogenic treatment of engine parts. A cryogenic treatment is the process of treating workpieces to cryogenic temperatures ie. As you can guess from the use of the word Cryo - it involves the cooling and heating of the engine. All parts must be free from grease and oil.

Cryogenic treatment of transmissions increases the life of all internal parts as well as the casing. Basically how cryogenic treatment works is this. If you cryogenically treat it it will change size much less which gives engine builders a greater measure of control over clearances.

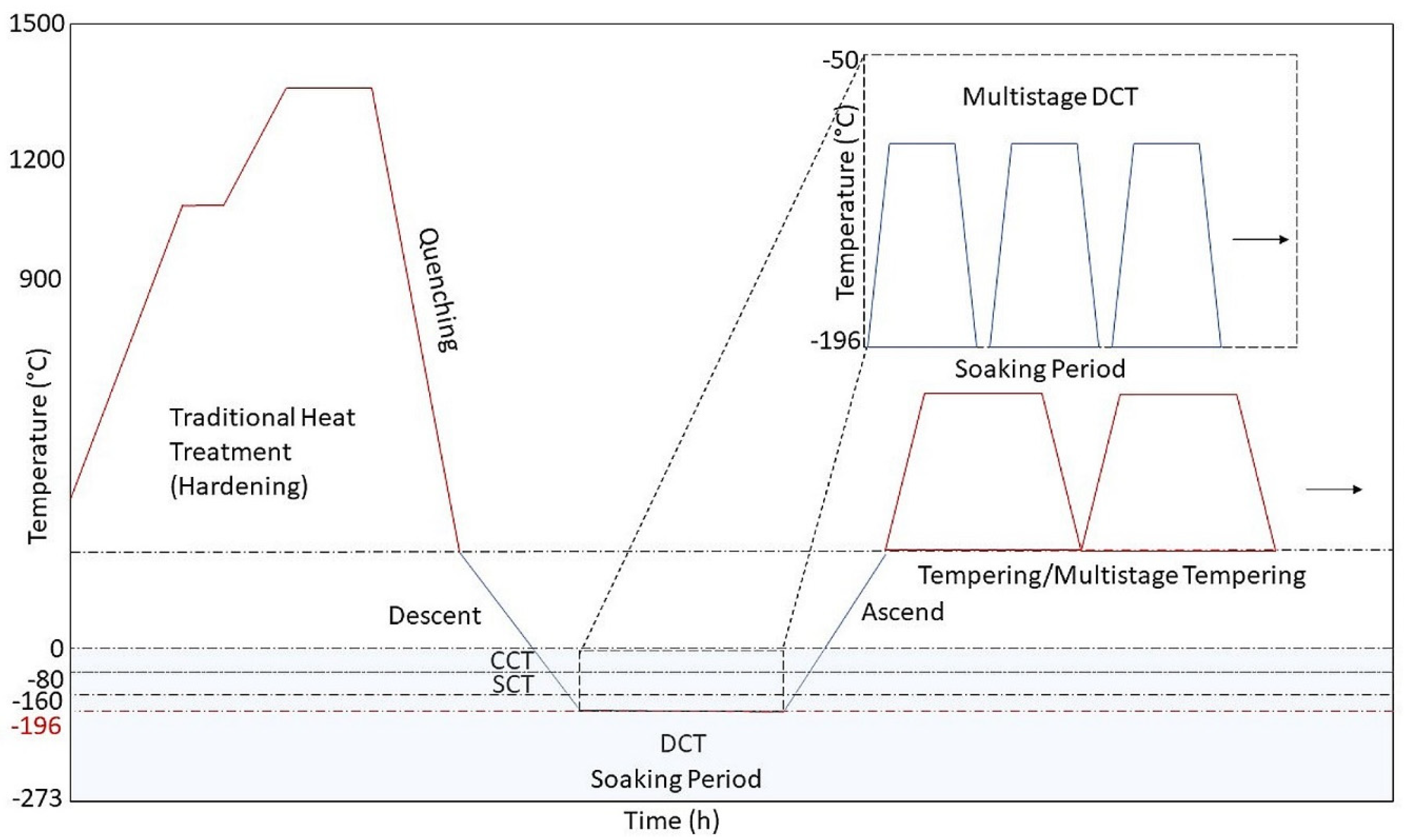

CRYOGENICALLY TREATED RACING ENGINES AND PARTS PERFORM BETTER UNDER HIGH STRESS CONDITIONS 300 Below Inc. Cryogenic Treatment of engine parts will increase the anti-wear properties of the metal. The chamber is sealed and the temperature is then slowly lowered to -320 F using liquid nitrogen.

Cryogenically Treated parts are far more dimensionally stable than their un-treated counterparts. Cryogenic Treatment has become the secret weapon of CHAMPION RACE CAR TEAMS and automotive enthusiasts alike. Sheet metal electrical parts water pumps oil pumps or fuel pumps should not be treated.

These changes are due to heat vibration or age. All parts that wear break or distort. More horsepower with less wear Increased Abrasive resistance toughness and tensile strength teamed with increased dimensional stability.

This is to say that the original heat treatment didnt fully transform. Is changing the face of Motorsports by applying the deep cryogenic tempering and treatment process to increases engine performance reduce wear and improve longevity. A parts life increasing 2-3 times is not uncommon.

It aides in converting retained austenite to martensite. Benefits of Treated Parts When left untreated a component can change in size and dimension.

If you cryogenically treat it it will change size much less which gives engine builders a greater measure of control over clearances.

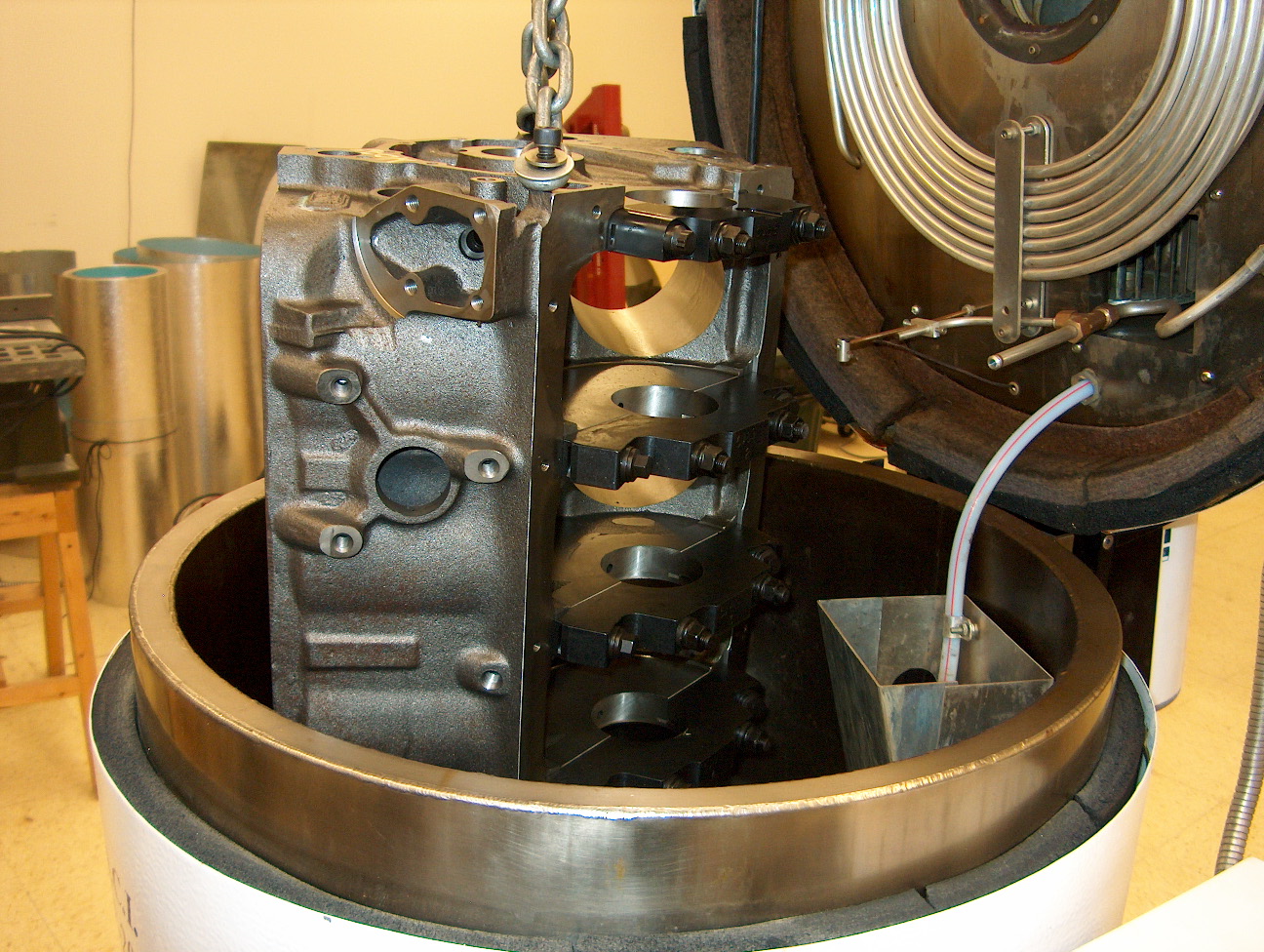

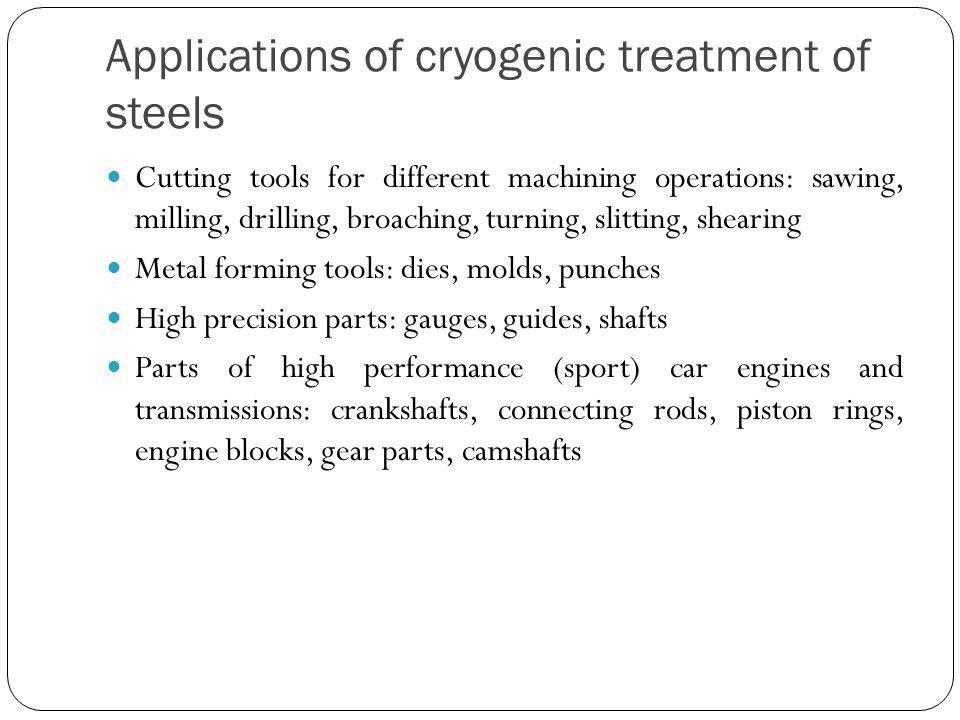

Below 190 C 310 F in order to remove residual stresses and improve wear resistance on. If you cryogenically treat it it will change size much less which gives engine builders a greater measure of control over clearances. Since all stress with-in a part is completely relieved the parts are far less likely to fail or break. CRYOGENICALLY TREATED RACING ENGINES AND PARTS PERFORM BETTER UNDER HIGH STRESS CONDITIONS 300 Below Inc. This is to say that the original heat treatment didnt fully transform. Engine Blocks Pistons Rings Cranks Valves Springs Cams that have undergone Cryogenic processing show marked performance and durability. NitroFreeze can treat both automatic and manual transmissions. Gear failure and wear are reduced. A parts life increasing 2-3 times is not uncommon.

Cryogenically Treated parts are far more dimensionally stable than their un-treated counterparts. Engine parts are much more wear resistant after Cryogenics. CRYOGENICALLY TREATED RACING ENGINES AND PARTS PERFORM BETTER UNDER HIGH STRESS CONDITIONS 300 Below Inc. Parts like crankshafts connecting rods and valve springs are far less likely to break. 36 linhas Cryogenically treated engines and components exhibit less wear and are less prone to. Cryogenic Treatment of engine parts will increase the anti-wear properties of the metal. Benefits of Treated Parts When left untreated a component can change in size and dimension.

Posting Komentar untuk "Cryogenic Treatment Of Engine Parts"